Automated Wash Down Diversion Systems

DD600 Automated Wash Down Diversion System

Ideal for outdoor and unroofed wash bays, the DD600 model is designed with a dedicated wash point, which signals a mechanical valve to open when wash taps are used. The wash water is then diverted to a holding tank or something similar, away from the stormwater network. At the end of the wash down procedure, the valve returns to the closed position shutting down the valve and returning the waters flow to stormwater under normal rain events. The pit needs to be cemented into the floor and a demand valve installed on the water supply line.

The DD600 protects the stormwater network from pollutants generated from wash-down activities and should be used on wash down systems when the area can be kept clean afterward. Dedicated and permanent structured wash down systems such as these generally requires a treatment system and connection to the sewer to create a closed loop system for the user. To discuss your wash-down options, Treatment options, pricing, and commercial viability calls us today.

Applications

Robust and reliable the diversion system is well suited to tough applications like truck and equipment washing, quarantine, mining and machinery applications.

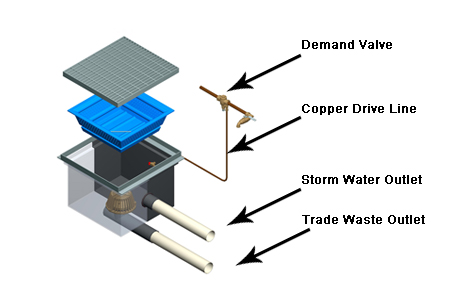

The Diversion valve system is housed in a 600 x 600 square poly pit and the pit has 2 outlets, one for stormwater and one for trade waste. The unit is fitted with a silt basket effectively protecting the valve from gross pollutants which can be easily removed for housekeeping. The diversion systems are available with standard and heavy duty grates with class B being standard.

How It Works

During rain events, the pit fills and water exits the stormwater pipe.

The Fox demand valve has the role of sending the signal into the pit for the valve to open or close. The demand valve is installed in a convenient area to the wash bay on the water supply line 100KPA required at a minimum. Any tap point after the demand valve effectively controls the movement of the valve there for any taps after the demand valve is a dedicated wash down tap. Simply turn on the tap and a hydraulic signal controls the valve and positions it open as long as the tap is on. Always remember to use water saving devices such as pressure washers on your wash bay – they save you money and increase time efficiencies.

During a wash application the DV150 valve automatically senses a wash down taking place and opens allowing the wash water to be diverted to the Trade Waste pipe.

Frequently Asked Questions

Is the diversion system expensive?

Does it need servicing? If so how often?

What is the invert level of the SW pipe on the system?

How effective are the silt baskets?

FF600 First Flush Diversion System

The first flush diversion system is very similar to the DD600 Automated Wash Down Diversion System except for one special design feature. The system comes with PLC control and can cleanse a site by handling a first flush volume when it begins to rain. The system is designed for wash areas that are too large to hose clean at the end of each and every washdown application.

The system can be programmed to divert a first flush volume up to 2000L on standard systems and still has the same demand driven diversion capabilities. Most regulatory authorities look for 10mm to 15mm first flush volume depending on applications meaning: 10mm on a 300m2 area would be 300L.

The first flush diversion system intelligence comes from the ability to program and control volumes easily from a PLC making it flexible and able to be used in many different applications.

The first flush components can be plate mounted compiling multiple valves and increasing flow rates and system capabilities to handle large-scale washdown applications. The system still has the demand-driven diversion capabilities, as well as fully pre-programmable first flush capabilities.

The system comes pre-packaged with a stainless control box housing the PLC and demand valve. The panel box is to be wall mounted and the associated cables run directly to the location of the pit underground shielded in conduit. A licensed plumber is required for copper drivel line and general pipe installations and an electrician should be used for any electrical works.

Frequently Asked Questions

How do I know if I need a First flush system or a straight diversion system?

Does it work the same as the diversion systems?

Supplying Products Anywhere in Australia

We are known for our timeliness on orders. We ship your in boxes, pallets, skids and containers and have access to a number of freight companies.