Silt curtains are deployed to avoid creating water turbidity during operations such as excavation, dredging, piling, and construction on and near shore. These geotextile floating booms represent a physical barrier that diverts disturbed soil sediment to the sea floor where it can settle instead of migrating up or down stream and into areas where silt ultimately can cause problems to the sensitive aquatic ecosystem. But how exactly do silt curtains work and how do you install them? How much does it all cost? Read on to find out.

The term “murky waters” is a metaphor for unreliability and a lack of clarity.i

Any business that contributes to creating literal murky waters – waterways clouded with sediment plumes – is in breach of their own environmental management and responsibilities and undoubtedly that can cause problems for the company both legislatively and socially.

That is why your company should aim to mitigate this negative consequence on shoreline projects and construction applications at all times.

Luckily, the modern palette of environmental protection equipment offers efficient and cost-effective ways to prevent accidental silt pollution of our waterways.

Silt curtains are at the frontline – or rather, are the frontline – in a battle to keep our waters clear and our businesses protected.

Still, that’s not the whole story. You may have been wondering:

- What does a silt curtain do?

- Are silt curtains hard to install?

- How much does it cost to install a silt curtain?

If so, this is the article to answer all your questions and help you totally understand why we use them and who should use them.

What Is A Silt Curtain?

Silt curtain, also known as Floating silt curtain, Floating silt barrier, Silt boom, or Turbidity curtain, is a key piece of environmental protection equipment that minimises physical water pollution usually by way of sediment control.

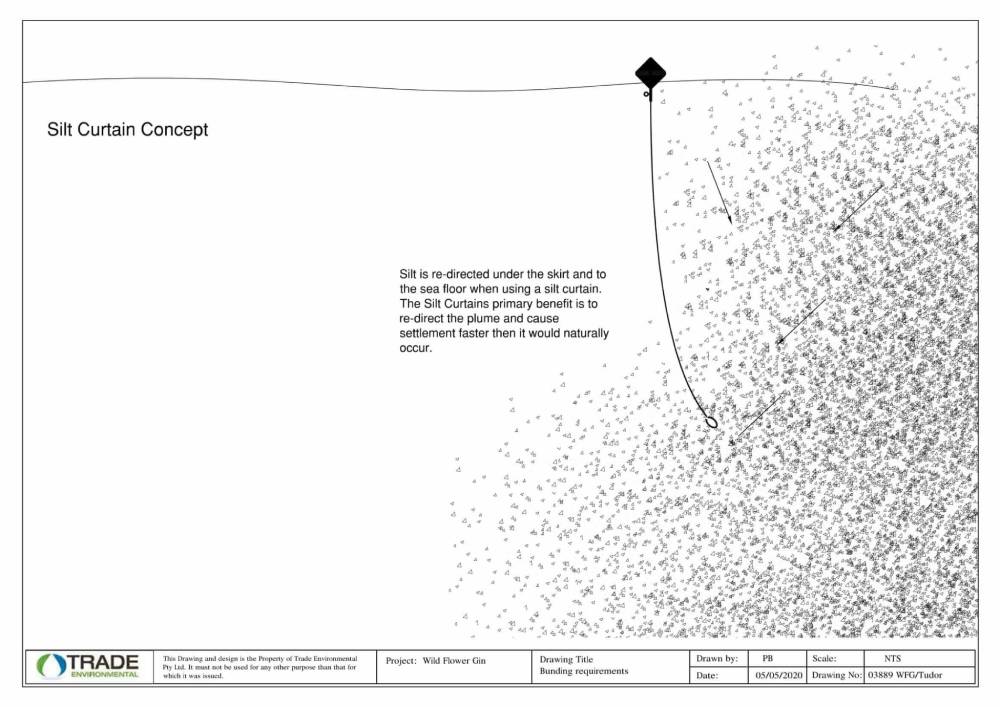

Excavation, construction, and other earthworks – especially near the shoreline – will inevitably saturate the bordering waterways with sediment. It is essential to stop the migration of the silt through the water column spread and allow it to settle in a controlled manner. The containment barrier provided by a silt curtain also ensures sediment settles as close to the area it was unsettled. Meaning a reduction in migrating sediment to areas where it wasn’t before. As an operator this is your job to reduce the migration of particles, caused by your operations into areas where it wasn’t before… In other words, we don’t want a plume of silt making its way from your worksite to a nearby area that could be sensitive, i.e. sea grasses, marine life habitats and other natural habitats for aquatic life.

The silt curtain is a semi-permeable barrier that is partially floating and partially submerged. It stops the soil particles from spreading in the water column and promotes their settling within the curtain’s borders. That way, it prevents an increase in water turbidity and a myriad of related negative environmental impacts.

The main work is done by the silt curtain skirt that sits perpendicular to the water column and is weighted down by an anchor system.

How Is Silt Curtain Installed?

Important note: We’re about to describe a generalised procedure of installing a silt curtain. However, the conditions vary considerably across job sites. Each installation is unique and requires some degree of customisation. Our experts carefully plan each installation depending on the crucial factors, including terrain conditions, access and the properties of the particular silt curtain model compared to that of tidal movements, actual flow and bathymetry.

Silt Curtain Installation Method

Step 1: The Unpacking

The silt curtain comes pre-packed in bundles. Bundles or curtain sections should be aligned on the site’s shoreline and placed close enough to one another to make attachment from one to the next easy. The space should be sufficient to lay out at least two sections of the curtain fully. Ensure that the area is free of sharp objects and abrasive surfaces to avoid any damage to the geotextile. Once everything is in place, the vinyl bundle straps near the end connecters are cut or untied so that skirt and float attachment can be done easily.

Step 2: The Assembly

Now it’s time to join the sections of the curtain together. At the end of each curtain segment, some types of curtains (often labeled as Type 1, 2 and Type 3) have aluminum section connectors or “slide connectors”. Joining these connectors is easy – simply slide them together and lock them in place by inserting toggle pins or the provided hardware into the aligned pre holes. Depending on conditions you can join up to 100m on the shoreline.

At each end of the silt curtain skirt, there are the slide connectors, multiple lengths can be put together to create the overall lineal requirement of the project. If the project requires more than 100m of silt curtains we advise running the first 100m out into the water to lessen the drag resistance before adding more sections… After the slide connectors are fitted, utilizing the marine zipper tag, fully zip up the skirt, shackle the ballast chains so the full depth of the skirt is now attached to each other at the connection point. It’s important to only untie/unfurl the sections at this stage near the connections. It’s easier to manoeuvre the floating silt curtain on the water with these ties done up again creating less drag and resistance when moving into place on the water.

Step 3: Preparation For Deployment

To prepare the curtain for deployment, you should fold it and pack it. The skirt should be folded in accordion style underneath the float elements as mentioned above. Then, re-tie the straps around both the skirt and the floats.

In some cases, the finalisation of silt curtain assembly happens at this point. The two curtain sections can be either bundled at the water’s edge or floated in a staging pattern until all sections are connected, and the entire length is made up.

Step 4: Deploying The Curtain

To deploy a curtain, tow it into a position and secure it to the anchors. Before towing, the skirt should be furled up and secured under the floats until the entire anchoring stage is done. This is how we can review and refine the layout, anchoring prior to unfurling the skirt. In other words once attached you should look at the layout and ensure your happy with its location prior to unfurling.

If required the shoreline can be temporarily covered in geotextile or tarp to avoid damaging the barrier while dragging it towards the water. We prefer to do this assembly as close to the waters edge as possible to again lessen the drag and load placed on the curtain.

Step 5: Anchoring

Proper anchoring is a vital phase of silt curtain installation, as it can profoundly affect the entire system’s stability and efficiency. Careful anchoring planning and calculations must be done before the installation, especially if the site’s waters are affected by currents, tides, or strong winds. These environmental conditions dictate anchoring design and placement. The best type of anchor to use also depends on the type of seafloor you’re dealing with at the time.

For small silt curtains in undemanding conditions, anchoring may be as simple as securing the silt curtain between two stakes on opposing shorelines. However, for large, long curtains in tricky situations, the process is much more complex. In the case of flowing water, the curtain should be oriented parallel to the water flow as much as possible. In case of tides and other challenging marine conditions where the curtain can face pressure from either side, the best practice is to anchor it from both sides. In some cases with strong tides, we would also recommend double anchoring on corners.

The general process of anchoring goes like this. First, you should drop the anchor ensuring the marker buoys fit into position and with the intended layout prior to connecting them to the silt curtain. Then, you attach the anchored buoy to the curtain via the tether line. The line is connected to anchoring points or section connectors along the curtain.

As you can (sense) from this generalized description, the silt curtain installation is best done in close cooperation with experienced users or experienced marine operators that understand flow dynamics.

Silt Curtain Installation Cost

Of course, at this point, you must be wondering about the floating silt curtain price.

As said, the field conditions dictate the details of installation – the silt curtain type, components, and materials.

Three main factors affect the silt curtain’s final price:

- The overall length and depth of the silt curtain

- Other customised technical properties of the curtain and the accompanying equipment.

- The climatic and environmental factors at the site.

- Mobilisation costs to and from site

- Overall time/hours required

Here’s a more detailed explanation.

Silt curtains designed for short-term deployments or calm waters with low exposure to adverse conditions will naturally be simpler and more affordable. Still, you wouldn’t want to install that type of curtain in restless waters with a pronounced tidal influence, strong winds, or other difficult weather conditions as it simply won’t last and could break. The last thing you want is to install a silt curtain twice or have an under-gunned silt curtain break free of its anchor and go on the move. For that reason there are different types that all have different characteristics, and load pressure ratings. Anyone selling a silt curtain should be knowledgeable toward options and site conditions to best recommend a fit for purpose option.

What Is Silt Curtain Hire (And How Does It Work)?

If your business requires a silt curtain only temporarily to complete a certain project, at Trade Environmental, we offer a service called Silt curtain hire.

The silt curtain hire is what it sounds like – you get to rent a silt curtain for your project at a significantly lesser expense than buying it.

Any more silt curtain installation questions? Let us know!

At Trade Environmental, we are happy to offer you a full range of services regarding silt curtains – planning, design, installation, maintenance, and removal. Our experienced team will be happy to consider each detail of your application and assess which type of barrier and anchoring is best suited for your needs. Call us today to find a perfect silt curtain solution for your business.